The emergency braking system of Xaori's rigid punching machine mainly consists of the following structures:

Emergency braking system transmission mechanism of punch press:

It mainly consists of a support, a pull rod, a lever, a force regulating spring, a gasket, a steel wire rope, a fixed pulley (selected according to the actual installation situation), etc. Mainly transmitting the pulling force of the driving mechanism to the friction belt.

Emergency braking system driving mechanism of punch press (electromagnet):

Provide power source for braking. Adopting patented technology - fast (response time 10-15ms), strong (maximum pulling force 90kg), highly reliable, and long-life electromagnets. Select electromagnets with different pulling forces and strokes based on different tonnage punch presses.

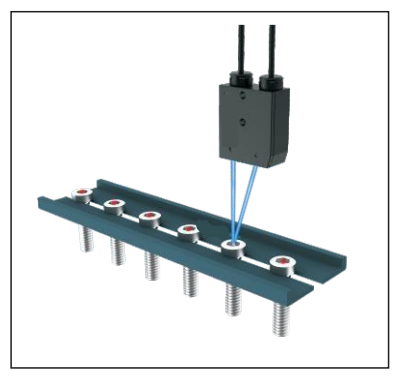

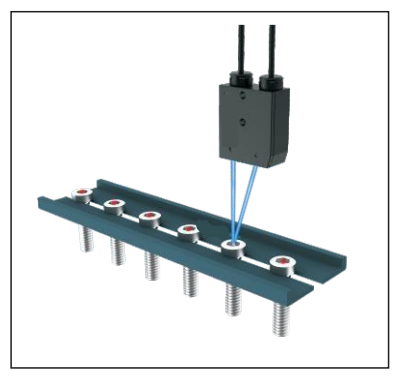

Light curtain:

The Light curtain detects whether the human hand enters the dangerous area. At present, the sensor is installed on both sides of the workbench using the opposite firing method.

Electric control box:

The control center of the entire system coordinates and processes the actions of various components, detects the status of each component, and provides functions such as fault detection and alarm.

Rigid punch emergency braking system slider position sensor:

A sensor used to detect the position of the slider. It mainly consists of a slider sensor assembly, magnetic separator, universal support, permanent magnet, etc.

The specially designed slider (punch) position sensor can effectively distinguish between hazardous areas and safe areas (the first stage of return and descent). Xaori's rigid punch emergency braking system only operates in hazardous areas, and the safe area is shielded from light without braking, making it convenient for loading and unloading, and meeting production needs to the greatest extent possible. Even after an emergency brake occurs, resuming production is very convenient, just like normal production operations, effectively solving the safety issues of punching machine operators. While ensuring production capacity, safety protection is achieved, which is different from the production impact of previous safety protection devices on operators.

+86-0755-29898410 +86-0755-29898460

+86-0755-29898410 +86-0755-29898460  ron@xaori.net

ron@xaori.net