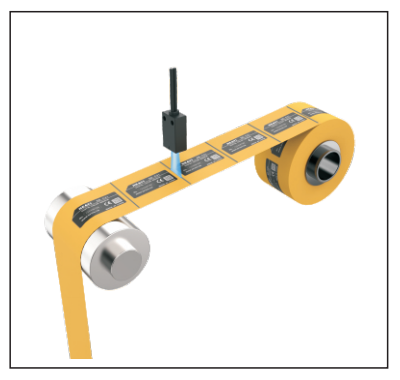

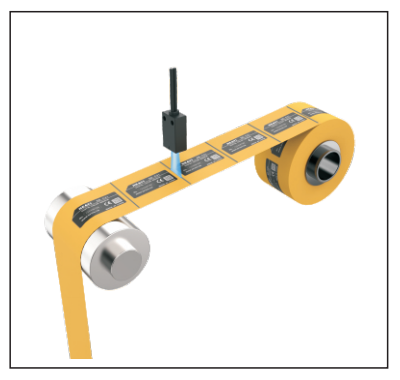

The safety grating is also a photoelectric safety protection device (also known as a safety protector, safety protection device, punching machine protector, infrared safety protection device, etc.) In modern chemical plants, humans and machines work together on potentially dangerous mechanical equipment, such as stamping machinery

Cutting equipment, metal cutting equipment, automated assembly lines, automated welding lines, mechanical conveying and handling equipment, hazardous areas (toxic, high-pressure, high-temperature, etc.) can easily cause personal injury to operators. The emergence of safety gratings is to solve this safety hazard. Optoelectronic safety devices emit infrared rays to generate a protective light curtain. When the light curtain is obstructed, the device sends a blocking signal to control potentially dangerous mechanical equipment to stop working and avoid safety accidents. The safety grating can effectively avoid the occurrence of safety accidents, avoid the danger of operators and third parties, reduce the comprehensive cost of accidents, and benefit the company itself, operators, and society.

Safety gratings and safety light curtains are mainly used in the following industries:

(1) For press machines where the slider can brake and stop at any position of the stroke, full protection can be achieved, or it can be combined with a cam switch to achieve protection of the stroke between 30 degrees and 180 degrees.

(2) For press machines where the slider cannot stop at any position of the stroke, the top dead center protection can only be achieved during a single operation, that is, after the end of the previous stroke, the next stroke has not yet started. If the photoelectric protection device is in a dark state, the next stroke cannot be started (sufficient safety distance must be ensured).

(3) This device is mainly used in forging machinery equipment.

(4) Used for industrial robots, injection molding machines, packaging equipment, paper cutting machines, filter presses, automation equipment, and welding processes.

+86-0755-29898410 +86-0755-29898460

+86-0755-29898410 +86-0755-29898460  ron@xaori.net

ron@xaori.net